2013 Mighty Viper LG-1000 VMC | 12k RPM | Under 7k Hours | Mitsubishi M70 | CAT-40

2013 Mighty Viper LG-1000 VMC | 12k RPM | Under 7k Hours | Mitsubishi M70 | CAT-40

$30,500 (USD)

Available quantity:1

Description

2013 Mighty Viper Model LG-1000 CNC Vertical Machining Center

High-Speed Linear Series | 12k RPM Spindle | Verified Low Hours

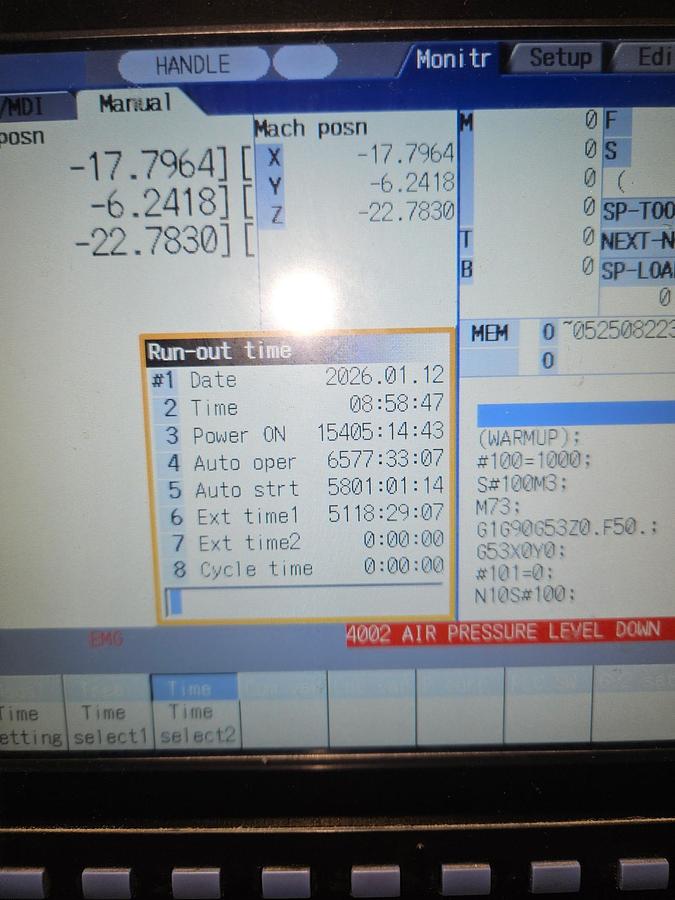

This 2013 Mighty Viper LG-1000 is an exceptionally clean, low-hour vertical machining center designed for high-speed precision. While most units of this age have seen heavy production, this machine features under 7,000 auto-operating hours, making it a rare find for shops looking for "near-new" performance at a used-market price point.

Engineered for speed and agility, the LG-1000 features a 12,000 RPM spindle and a high-speed Mitsubishi Hartrol-M70 control, making it the perfect choice for aluminum work, 3D mold surfacing, and high-efficiency medical or aerospace components.

Lemke Machinery Sales is pleased to offer this 2014-delivered (2013 build) Mighty Viper LG-1000. While most machines of this age are nearing major spindle or guide overhauls, this unit features under 7,000 verified auto-operating hours. It has been utilized in a light-duty environment, leaving the spindle and linear guides in excellent, production-ready condition.

The LG-1000 is the "Precision Speedster" of the Mighty Viper lineup. With its 12,000 RPM spindle and agile linear guide construction, it is the ideal solution for shops focused on aluminum components, medical parts, 3D mold surfacing, and high-efficiency job shop work

Machine Specifications (S/N 019821)

- Travels: 39.4" (X) x 20.1" (Y) x 25.0" (Z)

- Table Size: 45" x 20" (Heavy 1,540 lb Load Capacity)

- Spindle Speed: 12,000 RPM (High-Speed Direct Drive)

- Taper: CAT-40

- ATC: 24-Station Twin-Arm (Side Mount)

- Control: Mitsubishi Hartrol-M70 CNC

- Footprint: 1150mm x 510mm Working Surface

Performance-Driven Features

- Active Thermal Management: Equipped with a 2013 Harbor Spindle Oil Chiller (Model HBO-250PTSB4). This system circulates temperature-controlled oil to eliminate thermal growth, ensuring micron-level accuracy during high-speed, long-duration runs.

- Rapid Metal Removal: The 7.5 HP high-performance spindle motor combined with 12,000 RPM allows for faster feed rates and superior surface finishes in non-ferrous and light-alloy materials.

- Integrated Chip Management: Comes with a Fongex Incline Metal Chip Conveyor, saving your operators time and keeping the workspace clean during high-volume production.

- Superior Foundation: Built with high-rigidity linear guides and pre-tensioned ballscrews for high-speed rapids and precise repeatability.

Premium Features Included with S/N 019821

- Active Spindle Cooling: Includes a factory-installed Habor Spindle Oil Chiller (Model HBO-250PTSB4). This system is critical for maintaining thermal stability and accuracy during high-speed machining.

- Production Chip Management: Comes equipped with a Fongex Incline-Type Metal Chip Conveyor, ensuring efficient clearing and reduced downtime.

- High-Rigidity Linear Guides: Designed for fast rapid traverses and precise repeatability, ideal for complex surfacing and fine finishes.

- Operator Ready: Features include rigid tapping, a large work light, an automatic lubrication system, and a tri-color status light.

Dealer Note: "S/N 019821 is a 'turn-key' machine. With its current configuration—specifically the 12k spindle and the Habor chiller—it is ready for precision mold work or high-speed aluminum production immediately.

Specifications

| Manufacturer | Mighty Viper |

| Model | LG-1000 |

| Year | 2013 |

| Condition | Used |

| Serial Number | 019821 |

| Stock Number | J19-6 |

| S/N | 019821 |

| Oil Cooler S/N | LC223926 |

| * Taper | CAT-40 |

| * ATC | 24-Station Twin-Arm (Side Mount) |

| * Control | Mitsubishi Hartrol-M70 CNC |